| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : DPACK

Model Number : HSF-380S

Certification : IOS9001

Place of Origin : China Hebei Dongguang

MOQ : 1 Set

Price : Negotiate

Payment Terms : L/C, T/T

Supply Ability : 4 Sets/Month

Delivery Time : According To Product

Packaging Details : Wooden case or wrapping film

Automatic level : Fully automatic

Working width : 1400-2500mm

Material : Casting ,spheroidal graphite 500

Speed : 220m/min

Weight : 2200type 15T 1800type14T

Type(Vacuum suction/another) : Inner suction

Machine Description:

Single facer is design for producing single-face corrugated paper, the medium process into wave-paper, and past glue

on the top of flutes, stick with liner become into single-face corrugated paper.

*With multiple corrugated roller ( B, E ,C,F,G)

*The design of corrugated roller positioned under the pressure roller, considering to reduce the center of gravity and reduce the vibration when the machine is running, insure machine running smoothly and steady. Because the corrugated roller position lower, so fast change roller more quickly, convenience, safety

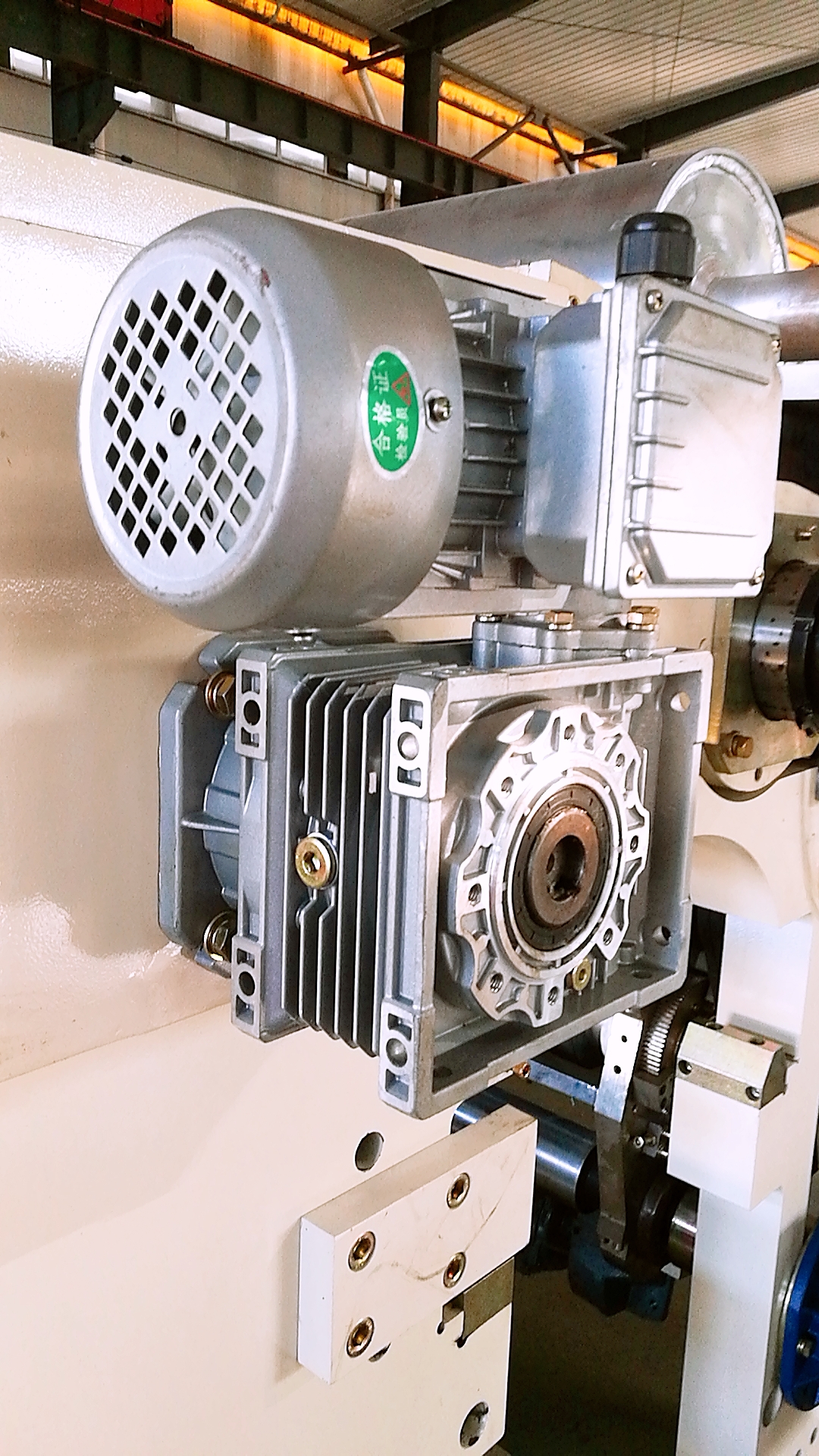

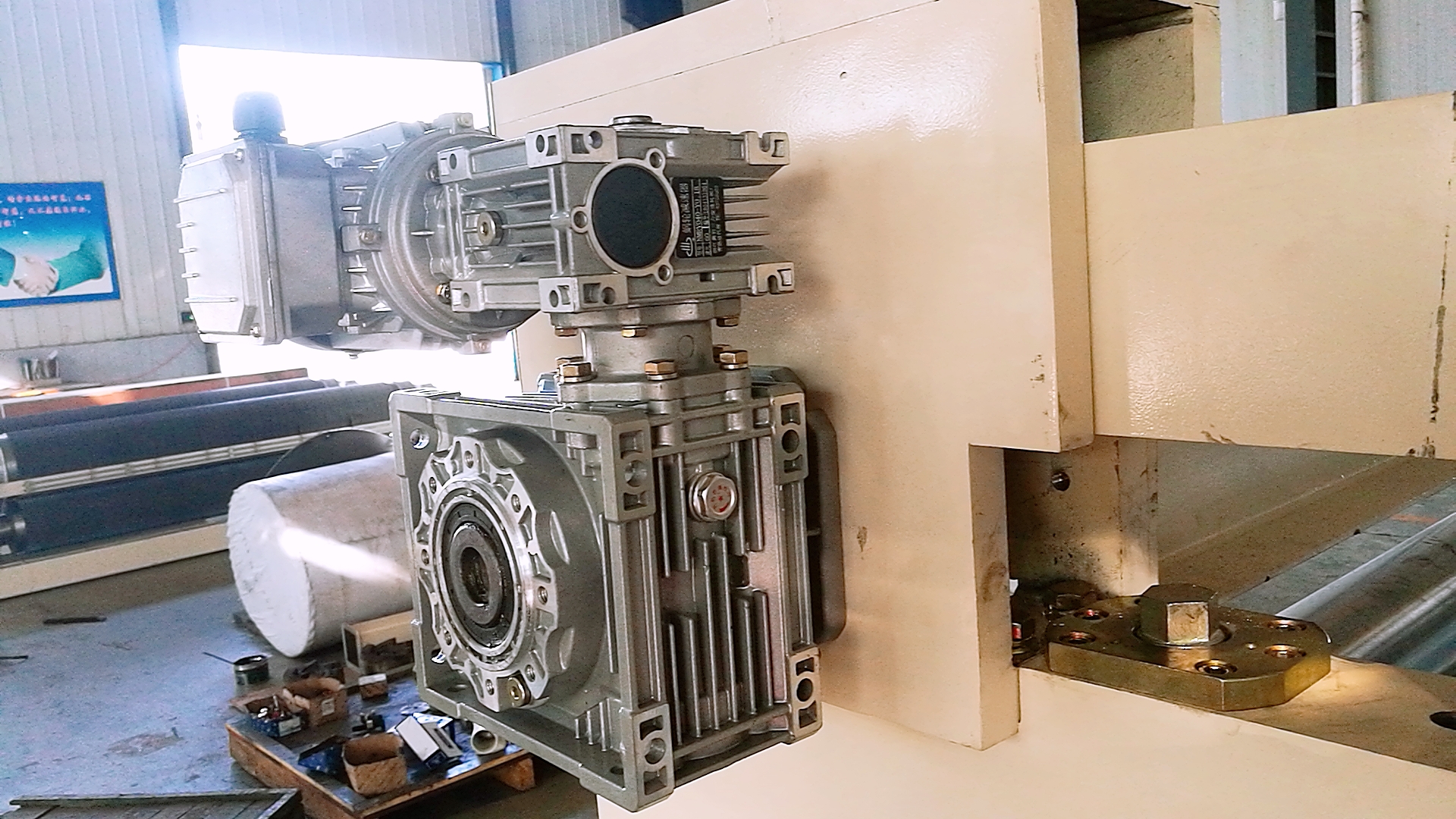

*The lubricating system of corrugated roller and pressure roller, adopt High Temperature Greases, can avoid the circulation oil easy to produce oil leakage or carbonization phenomenon and cause bearing damage.

*Corrugated roller, pressure roller, gluing roller adopt pneumatic control, have the pressure control of balance in the slow effect, of each roller gap adjusting with pressure control, which can solve the A.C motor for wet, high temperature and vibration caused by factors to the damage of the trouble.

*Quickly change roller 10mins,change corrugated roller use electromotion trolley carry it, the whole part move from main machine.

*Movable type gluing unit adopt independent transmission convenience to clean and maintain.

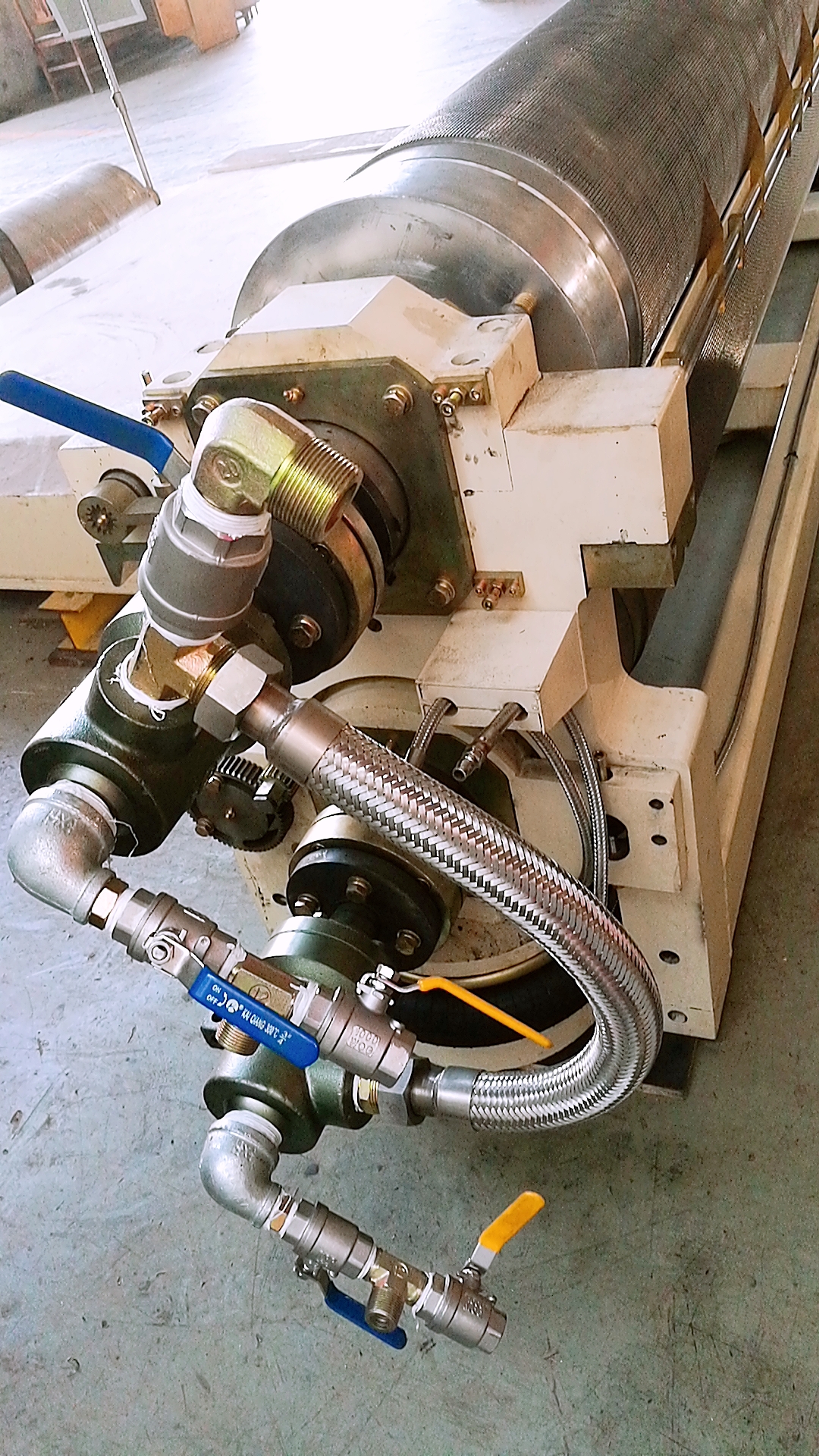

*The inlet and outlet of steam focus on one connect plate, connection controlled by pneumatic, convenient and quickly

*Corrugated roller, pressure roller and gluing unit controlled by pneumatic

*Quick change the corrugated roller in appr. 5~10 mins

*Design speed:200m/min

*¢380mm,adopt 48CrMo alloy steel,surface do tungsten carbide treatment,

Pressure roller 400mm

Gluing roller 288mm

Doctor roller 160mm

Pre-heater roller 400mm

Steam fast change: fast insert type convert steam, convenience and flexible

Main motor 45kw

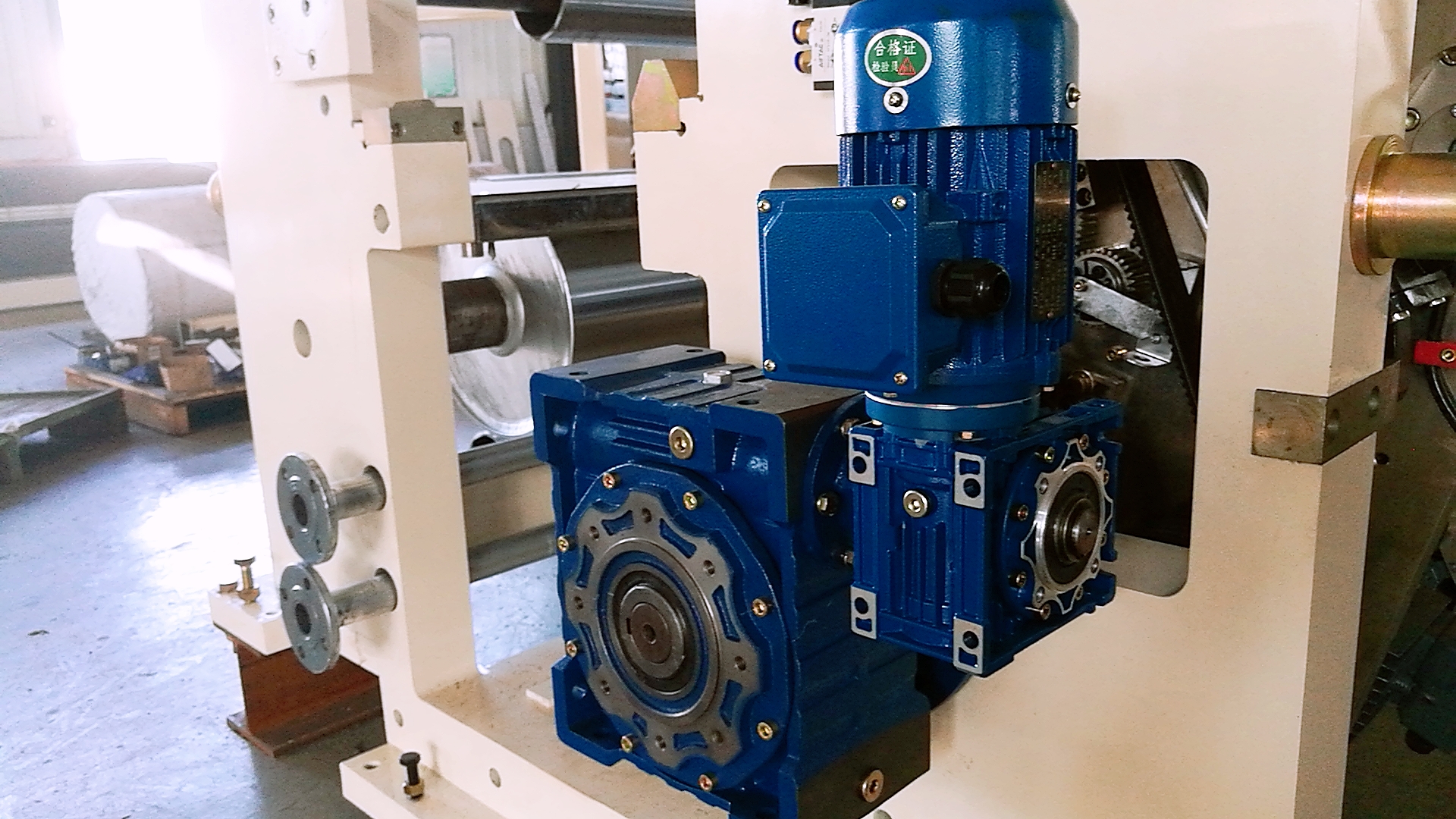

Gluing part driven motor 4kw

Gluing area motor 200w 2sets Taiwan brand

Main electrical adopt ABB SCHNEIDER brand

| Automatic level | Fully automatic | Working width | 1400-2500mm |

| Material | Casting ,spheroidal graphite 500 | Speed | 220m/min |

| Voltage | Determined according to client’s voltage | Power | 64kw |

| Weight | 2200type 15T 1800type14T | Usage | 3/5/7 ply |

| Size | 5400*1550*1600mm 1800type | Drive type | Electric/Pneumatic/Another |

| Types of corrugating | Chrome plated / Tungsten carbide | Packaging type | Main engine overall packaging |

| Type(Vacuum suction/another) | Inner suction | Certification | IOS9001 |

Bright spot HSF-380S Cassette Single Facer:

Independent main drive: Interface displays values:

Rotary gluing of the gluing part, good stability: Electric adjustment of the gap between gluing roller and corrugated roller, electric adjustment of glue amount

Electrically adjust the side of pressure roller clearance: Pressure roller‘s gap can be electrically adjusted:

Steam spray system:

|

|

Dpack corrugator Cassette Type Corrugated Board Machine / Automatic Corrugation Machine paper board production line Images |